Understanding Displacement Water Pumps

The displacement water pump plays a crucial role in various engineering and industrial applications. From auto repair shops to farm equipment repair, these pumps offer robust solutions for managing water flow and controlling fluid dynamics. In this comprehensive guide, we will explore the mechanisms, types, applications, and benefits of displacement water pumps, equipping you with valuable knowledge to make informed decisions for your business.

1. What is a Displacement Water Pump?

A displacement water pump is designed to move water or other fluids through a system by creating a pressure differential. These pumps operate based on the principle of displacing a fixed volume of fluid within a defined space. When the pump operates, it fills the chamber with fluid and then forces it out, ensuring efficient and reliable fluid transport.

2. Types of Displacement Water Pumps

Displacement water pumps can be categorized into two primary types: positive displacement pumps and dynamic displacement pumps. Each type offers unique mechanisms and applications.

2.1 Positive Displacement Pumps

Positive displacement pumps move fluid by trapping a fixed amount and forcing it into the discharge pipe. These pumps are often used in applications requiring high pressure and are suitable for handling viscous fluids. There are two main types:

- Rotary Pumps: These pumps utilize rotating elements to move fluids. They are known for their efficiency and ability to handle various fluid viscosities.

- Reciprocating Pumps: These pumps operate using a piston or diaphragm that moves back and forth to displace fluid. They are commonly used in applications requiring precise flow rates.

2.2 Dynamic Displacement Pumps

Dynamic displacement pumps, also known as centrifugal pumps, create flow by converting kinetic energy from a rotating impeller into hydraulic energy. They are typically used for applications requiring high flow rates and low pressure. However, they are less effective in handling viscous fluids compared to positive displacement pumps.

3. Working Principle of Displacement Pumps

The working principle of a displacement water pump hinges on the movement of fluid through a series of chambers. Let’s break down the process:

- Fluid Intake: The pump creates a vacuum that draws fluid into the chamber.

- Fluid Displacement: As the pump operates, it seals off the incoming fluid and forces it into the discharge pipe.

- Fluid Delivery: The displaced fluid exits the pump, completing the cycle.

4. Applications of Displacement Water Pumps

Displacement water pumps are versatile and find applications in numerous industries. Here are some prominent uses:

4.1 Auto Repair

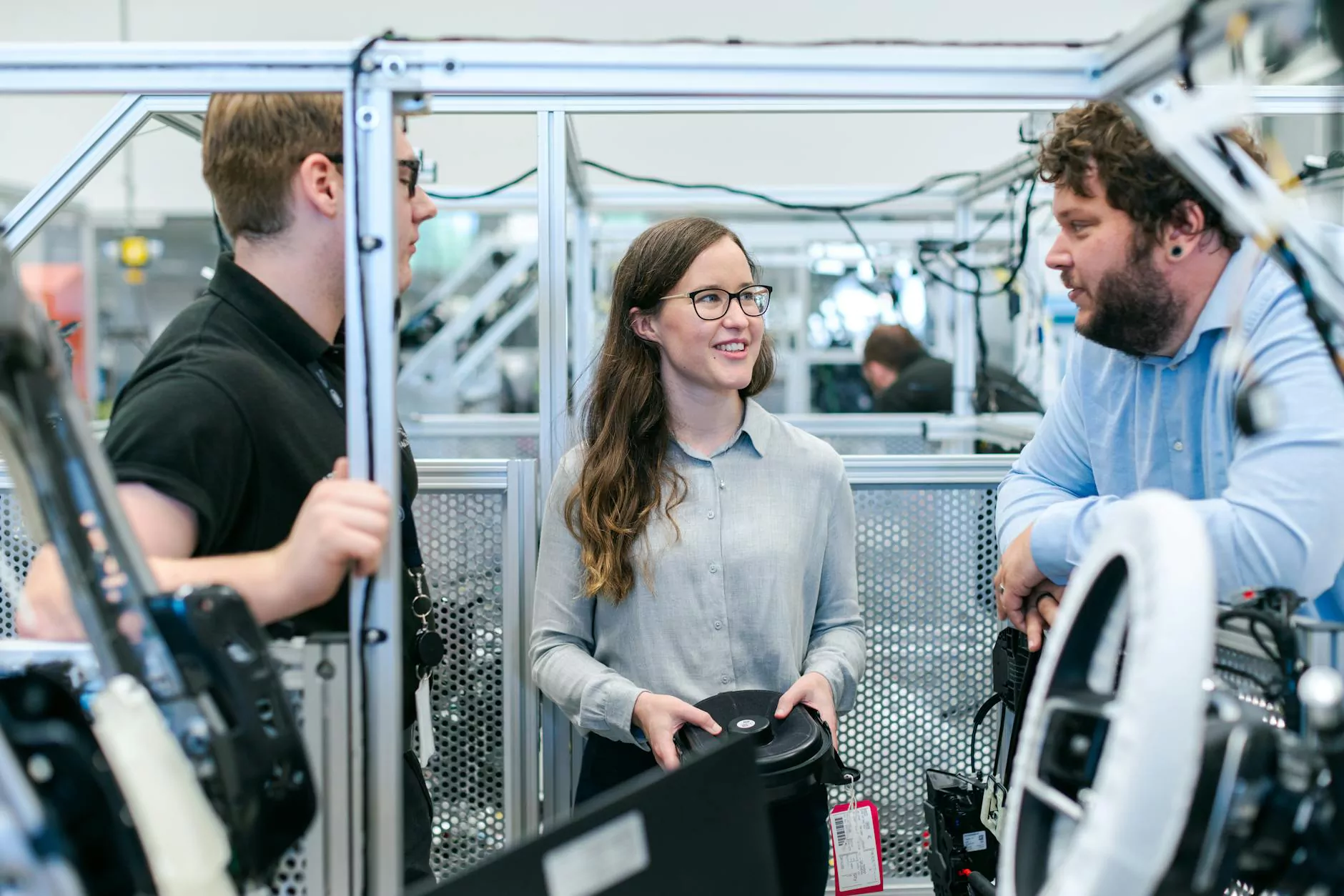

In the auto repair industry, displacement pumps are crucial for:

- Transferring coolant fluids.

- Flushing out fuel systems.

- Extracting waste oil from vehicles.

4.2 Farm Equipment Repair

Farmers and agricultural engineers utilize displacement water pumps for:

- Irrigation systems to ensure optimal crop growth.

- Drainage solutions in fields to prevent waterlogging.

- Transporting liquids for various farm operations.

4.3 Structural Engineering

In structural engineering, these pumps are essential for:

- Removing water from construction sites.

- Performing dewatering during foundation work.

- Fluid delivery for construction equipment operations.

5. Advantages of Using Displacement Water Pumps

Choosing displacement water pumps offers numerous benefits for businesses, including:

- Efficiency: They provide a consistent flow rate that is crucial for many applications.

- Versatility: Suitable for a range of fluids, including those with high viscosity.

- Durability: Designed to withstand harsh operating environments.

- Maintenance Ease: Many models require fewer maintenance interventions compared to dynamic pumps.

6. Selecting the Right Displacement Water Pump

When selecting a displacement water pump for your business, consider the following factors:

6.1 Flow Rate and Pressure Requirements

Evaluate the required flow rate and pressure for your specific application. This knowledge will help you choose the appropriate pump size and type.

6.2 Fluid Characteristics

Understand the viscosity, temperature, and chemical compatibility of the fluid your pump will handle. Selecting a pump that accommodates these characteristics is crucial for effective operation.

6.3 Maintenance and Availability of Parts

Consider the availability of spare parts and the ease of maintenance. Pumps with easily replaceable components will minimize downtime and operational costs.

7. Maintenance of Displacement Water Pumps

Proper maintenance is key to ensuring the longevity and efficiency of displacement water pumps. Here are essential maintenance tips:

7.1 Regular Inspections

Conduct regular visual and operational inspections to identify any wear and tear issues. Pay attention to:

- Leaking seals.

- Noisy operations indicating worn bearings.

- Corrosion on components.

7.2 Fluid Quality

Monitor the quality of the fluid being pumped. Contaminants can lead to premature wear and damage.

7.3 Lubrication

Ensure that all moving parts are properly lubricated to prevent friction and wear. Use manufacturer-recommended lubricants for optimal performance.

8. The Future of Displacement Water Pumps

The future of displacement water pumps is promising, with advancements in technology paving the way for more efficient and environmentally friendly options. Innovations may include:

- Smart Pump Technology: Integrating IoT devices for real-time monitoring and efficiency optimization.

- Eco-friendly Materials: Development of pumps using sustainable materials for a reduced environmental footprint.

- Energy-efficient Designs: New designs that lower energy consumption while maximizing output.

Conclusion

In summary, the displacement water pump is a vital component in many industries, including auto repair, farm equipment repair, and structural engineering. By understanding their types, applications, advantages, and maintenance needs, you can make informed choices that enhance your operational efficiency. Whether you're selecting a pump for a new project or maintaining an existing system, leveraging the unique benefits of displacement water pumps can lead to significant improvements in performance and reliability.

As the industry evolves, staying updated on innovations in pump technology will further empower your business to thrive in a competitive landscape. At Michael Smith Engineers, we are committed to providing high-quality solutions tailored to your specific needs. Invest in the right equipment today and watch your operational efficiency soar!